Clay and Soil

| M130262 | |

| Geology / mineralogy | |

| < 30 mm | |

| < 2 mm | |

| 100 g | |

| Desired amounts of sample can be ground with several machines. We recommend using a Cross Beater Mill PULVERISETTE 16. Also a planetary mill can be used for a comminution of such sample amounts. |

|

|

Cross Beater Mill PULVERISETTE 16 (cast iron grinding insert) |

|

| Equipment: |

bottom sieve 2,0 mm trapezoidal perforation |

|

|

|

sample: clay

|

|

|

|

115 g | |

|

|

< 1,5 cm (pre crushing might be required for some pieces) | |

|

|

~ 30 s | |

|

|

< 2 mm | |

|

|

With maximum 3 cm start size, a few particles use to be too big to be fed into the feeding funnel. It is recommended placing the sample into a plastic bag and comminution the sample with a few strokes of a hammer previously. Also a Jaw crusher will be capable to pre grind the sample.

The grinding sound stopped after ~ 15s. No further output has been found in the collecting vessel after a total of 30 seconds. The majority of sample has been ground successfully. A bit of material use to stick between the ribs of the grinding insert.

Even higher amounts of sample can be ground this way.

The grinding insert can be cleaned by grinding a small portion of sand. Afterwards, majority of residues can be removed by vacuuming with a soft brush.

|

|

| Pictures: |

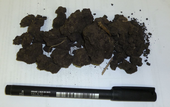

Start size of clay; also a comminution inside the feeding funnel (with a chisel or a screw driver) is possible. |

|

|

Opened grinding chamber -Only a bit of sample use to stick to the grinding inserts ribs after comminution. A grinding of higher amounts should be possible without problems. |

|

|

| Sample which has been ground with a 2,0 mm bottom sieve. Also inserts with smaller openings should be possible for grinding. |

|

|

|

|

Cross Beater Mill PULVERISETTE 16 (cast iron grinding insert) |

|

| Equipment: |

bottom sieve 2,0 mm trapezoidal perforation |

|

|

|

sample: soil

|

|

|

|

115 g | |

|

|

< 1,5 cm (pre crushing might be required for some pieces) | |

|

|

~ 20 s | |

|

|

< 2 mm | |

|

|

With maximum 3 cm start size, a few particles use to be too big to be fed into the feeding funnel. Even when sample will be comminuted with e.g. a screw driver inside of the feeding funnel, sample pieces can jam the opening of the feeding funnel. With a first trial, that happened and only an output of ~ 40 g have been achieved therefore (see plastic bag 2a). It is recommended placing the sample into a plastic bag and comminute the sample with a few strokes of a hammer previously (as we did with sample bag 2b).

The grinding sound stopped after ~ 20s. The majority of sample has been ground successfully. A bit of material use to stick between the ribs of the grinding insert.

Even higher amounts of sample can be ground this way.

The grinding insert can be cleaned by grinding a small portion of sand. Afterwards, majority of residues can be removed by vacuuming with a soft brush.

|

|

| Pictures: |

Also the start size of soil sample uses to be too big. To avoid a jamming of the feeding funnel, sample should be placed inside a plastic bag and previous comminuted with a few strokes of a hammer. |

|

|

On the left side, you can spot several pieces inside of the feeding funnel. This sample has been ground with result 2a. For the second trial, we only used pieces < 1,5 cm to avoid a jamming. |

|

|

| Sample after grinding with a bottom sieve of 2,0 mm trapezoidal perforation. |

|

|

|

|

Planetary Mono Mill PULVERISETTE 6 classic linemain disk speed: 650 rpm |

|

| Equipment: |

80 ml grinding bowl made of silicon nitride (Si3N4) + 5x 20 mm Ø Si3N4 grinding balls |

|

|

|

sample: clay

|

|

|

|

25 g | |

|

|

< 1 cm | |

|

|

30s | |

|

|

sticking stronger | |

|

|

Just for demonstration, we prepared a trial with smaller amounts of both samples with a planetary mill. An equal result will be achieved with a 250 ml grinding bowl as well (which should be suitable for a grinding of up to 100 g of sample as required). With just 30 seconds of grinding, sample became compressed to the wall of the grinding bowl. Sticking sample can be removed with a scraper. A longer dry grinding is not possible. To achieve a better fineness, a grinding in suspension will be required. For an intensive cleaning, sand and water have been ground for 1 minutes.

|

|

| Pictures: | Opened silicon nitride bowl with 20 mm Ø grinding balls. Sample already starts to stick to bowl and balls. A longer dry grinding is not recommended. To achieve a better fineness, a grinding in suspension might be required. |

|

|

|

Planetary Mono Mill PULVERISETTE 6 classic linemain disk speed: 650 rpm |

|

| Equipment: |

80 ml grinding bowl made of zirconium oxide (ZrO2) + 5x 20 mm Ø ZrO2 grinding balls |

|

|

|

sample: soil

|

|

|

|

25 g | |

|

|

< 1 cm | |

|

|

30s | |

|

|

sticking stronger | |

|

|

Just for demonstration, we prepared a trial with smaller amounts of both samples with a planetary mill. An equal result will be achieved with a 250 ml grinding bowl as well (which should be suitable for a grinding of up to 100 g of sample as required).

With just 30 seconds of grinding, the soil sample became compressed stronger to the wall of the grinding bowl. Sticking sample can be removed with a scraper. A longer dry grinding is not possible. To achieve a better fineness, a grinding in suspension will be required.

For an intensive cleaning, sand and water have been ground for 1 minutes.

|

|

| Pictures: | Opened zirconium oxide bowl with 20 mm Ø grinding balls. The soil sample use to stick stronger to bowl and grinding balls as clay did. This might be espoused by higher impact force of zirconium oxide balls (because of its higher density). Also with this trial, no longer dry grinding is possible. Only by grinding in suspension, a better fineness can be achieved. |

|

FRITSCH GmbH - Milling and Sizing

55743 Idar-Oberstein