This is how FRITSCH works

We can essentially only control what we actually produce. This is why all FRITSCH-products are manufactured according to special, constantly verified quality standards at our German headquarters in Idar-Oberstein – with an extensive in-house production depth that is one of our particular strengths. All steel, aluminium and stainless steel metal parts are milled and turned in our CNC prefabrication area. Purchased items such as plastic housing and sheet metal parts are predominantly sourced from long-standing partners in Germany. Our production is meticulously performed manually in small batches by experienced, specialised personnel. With no assembly line and no piece work. This close connection is important to us and is a key condition for that special FRITSCH-quality.

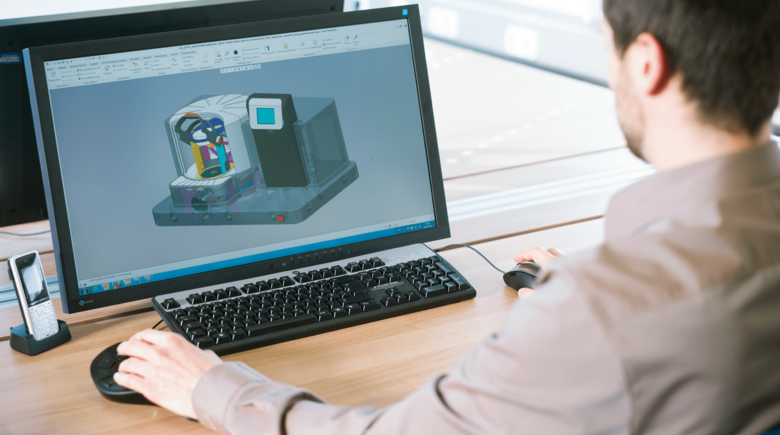

Our in-house development department produces new models from the initial idea right through to the prototype, which is prepared for production after a series of endurance tests – always inspired from your practical work routine as well as from intense interaction with the FRITSCH laboratory.

FRITSCH laboratory instruments – synonymous with quality

For this reason, the company concerned itself with quality assurance at an early point and received DIN EN ISO 9001 certification in 1994 as one of the first laboratory instrument manufacturers to do so.

All FRITSCH instruments bear the CE mark. FRITSCH laboratory instruments therefore offer an optimal solution for further improving the effectiveness of the QM systems of a company.

Uyghur Forced Labor Prevention Act (UFLPA)

Fritsch GmbH continuously monitors its supply chains to ensure that goods delivered to us have not been produced under forced labor in China. Fritsch GmbH can prove the origin of the products used at any time on the basis of production parts lists, delivery bills, invoices and payment receipts.

ISO 14001:2015 Certificate

ISO 14001 is a globally recognized basis for environmental management systems since 1996 & covers all aspects of continuous improvement in environmental performance. It defines the establishment, implementation, maintenance & continuous improvement of an environmental management system.

DIN EN ISO 9001 Certificate

The management system of FRITSCH has been assessed and certified as meeting the requirements of ISO 9001:2015!

Authorised Economic Operator – (AEO-F) certified

FRITSCH as Authorised Economic Operator – (AEO-F) certified: This seal of quality identifies the FRITSCH GmbH since the end of October 2008, as a “safe partner in trade” towards custom offices and customers.

Conformity declarations on WEEE

Conformity with WEEE ("Waste of Electrical and Electronic Equipment"), RoHS ("Restriction of certain Hazardous Substances in electrical and electronic equipment") and the Electrical and Electronic Devices Act.

Conformity declarations on RoHS

Conformity with WEEE ("Waste of Electrical and Electronic Equipment"), RoHS ("Restriction of certain Hazardous Substances in electrical and electronic equipment") and the Electrical and Electronic Devices Act.

Conformity declarations on RoHS (China RoHS)

Conformity with WEEE ("Waste of Electrical and Electronic Equipment"), RoHS ("Restriction of certain Hazardous Substances in electrical and electronic equipment") and the Electrical and Electronic Devices Act.

REACH

REACH (Registration, evaluation and authorization of chemical substances) - is a regulation in regards to the registration, evaluation and authorization of chemical substances.

Battery Ordinance

The German Battery Ordinance shall reduce the admission of harmful substances in garbage by forbidding that certain contaminant-laden batteries are sold as well legally binding the merchants to take back used batteries.

Conflict Minerals Policy Statement

Fritsch GmbH supports the goal of ending violence, human rights violations and envi-ronmental devastation in the Covered Countries. We are committed to complying with any requirements applicable to our Company under the Conflict Minerals Rule.